How Toyota Changed The Way We Make Things

Short Summary:

The video explores how Toyota's Production System (TPS), a revolutionary approach to manufacturing, transformed global production methods. Key elements include "Just In Time" inventory management, the Kanban system (a visual scheduling method), and a focus on continuous improvement ("Kaizen"). TPS emphasizes eliminating waste, improving efficiency, and empowering workers to identify and solve problems. Its impact extends far beyond the automotive industry, influencing manufacturing, technology, and even healthcare through its adoption by companies like Boeing and Intel, and even a Canadian hospital. The system's success is attributed to its ability to produce high-quality products faster, cheaper, and better.

Detailed Summary:

The video is structured chronologically, tracing Toyota's journey from post-WWII Japan to its global dominance.

Section 1: Post-War Japan and Toyota's Origins: Post-war Japan faced material shortages, forcing companies to innovate. Toyota, founded by Kiichiro Toyoda, inherited a culture of efficiency from its loom-making origins, leading to resourceful practices like reducing the Model K truck's features due to material scarcity. This early experience laid the groundwork for their lean approach.

Section 2: The Birth of the Toyota Production System (TPS): A trip to the US by Eiji Toyoda and Taiichi Ohno, observing Ford's massive River Rouge plant and a Piggly Wiggly supermarket, inspired the "Just In Time" (JIT) system. Ohno was impressed by the supermarket's customer-choice model, adapting it to manufacturing by producing parts only when needed, minimizing inventory and capital investment. The Kanban system, a visual signaling method for managing production flow, was also developed, acting as a precursor to barcodes.

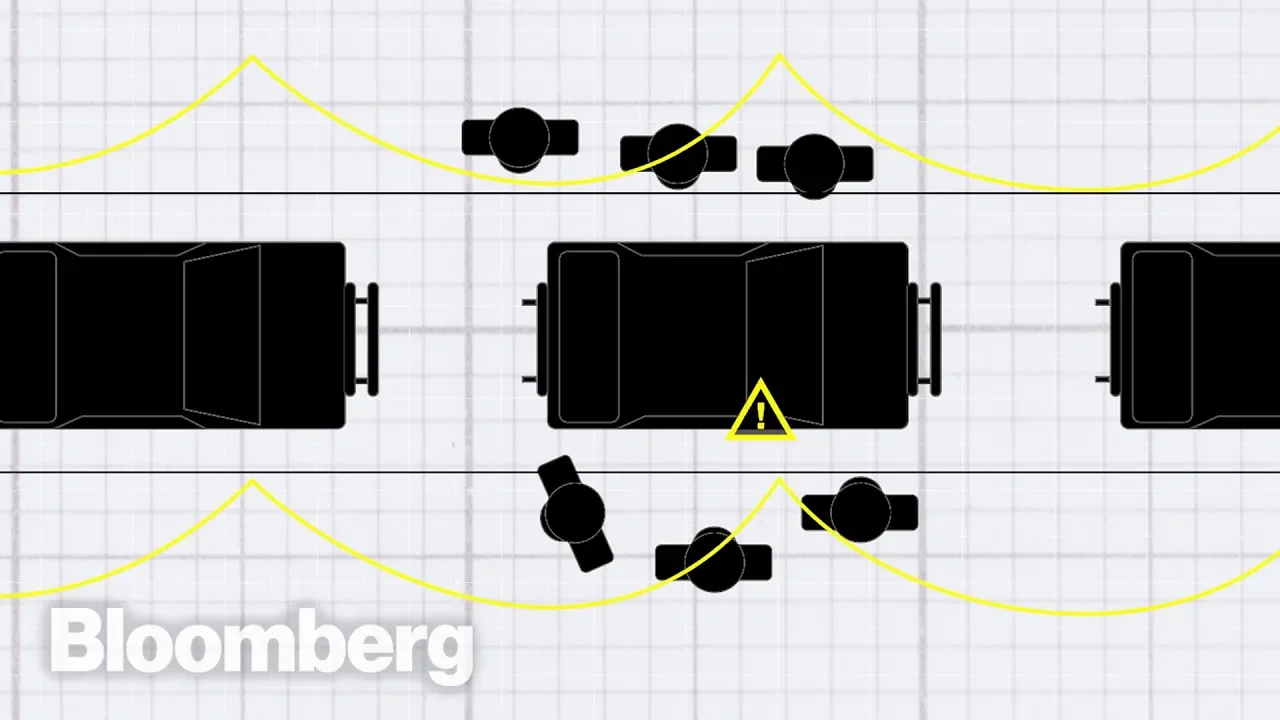

Section 3: Key Elements of TPS and its Advantages: The video highlights the contrast between Ford's "full-tilt" production and Toyota's approach. Toyota empowered workers with "andon cords," allowing any worker to halt the assembly line to address problems, fostering a culture of immediate problem-solving and continuous improvement (Kaizen). This proactive approach, combined with JIT and Kanban, dramatically reduced errors and increased efficiency. The result was a significant increase in production speed and a reduction in man-hours per vehicle. The affordability and fuel efficiency of Toyota cars also became a major advantage during the oil crises.

Section 4: The Legacy of TPS: The video concludes by emphasizing the widespread adoption of TPS principles ("Lean Manufacturing") across various industries. Examples include Boeing's plant restructuring, Intel's application to AI and IoT, and a Canadian hospital's use of TPS to reduce ER wait times. The video asserts that TPS not only revolutionized car manufacturing but also changed how we approach production in general, demonstrating that there's always room for improvement. There is no direct quote from a speaker, but the overall message emphasizes the transformative impact of TPS and its enduring relevance.