Training: Aerospace Manufacturing Readiness

Short Summary:

This training video details the aerospace composite manufacturing process, emphasizing the seemingly paradoxical nature of the work: highly precise yet achievable with average skills and diligent practice. The video covers the entire process, from mold preparation and prepreg layup to curing, trimming, sanding, drilling, and final assembly, highlighting the critical role of documentation and process specifications. Specific technologies like prepreg carbon fiber, autoclaves, and various fastening methods are discussed. The implications are the creation of high-quality, lightweight, and strong aerospace components. Detailed processes like mold integrity checks, layup, debulking, and final bagging are explained step-by-step.

Detailed Summary:

The video is structured as a comprehensive guide to aerospace composite manufacturing, broken down into several key sections:

1. Introduction and Documentation: The video begins by stating that aerospace composite manufacturing, while complex in its precision, is achievable with average skills, attention to detail, and practice. It emphasizes the critical importance of following detailed process specifications and documentation, which are not suggestions but requirements ("they are not suggestions, they are requirements"). This documentation covers part specifications, materials, tooling, and temperature-sensitive material tracking.

2. Materials and Prepreg: The video introduces textile reinforcement (unidirectional and woven fabrics – warp and weft), prepreg carbon fiber (resin-impregnated fabric), and the use of fiberglass plies for corrosion protection. The limited shelf life of prepreg and the importance of meticulous tracking of its "out time" are stressed. The concept of the "warp clock" is introduced to explain the precise orientation of prepreg plies (0°, ±45°, 90°) during layup, emphasizing that the work instructions always specify warp orientation, not template orientation.

3. Mold Preparation and Integrity Check: This section details the inspection, cleaning, sealing, and preparation of molds. A crucial step is the mold integrity check, which involves cleaning, applying tacky sealant tape, placing a breather layer, installing vacuum ports, and bagging the mold to test for leaks. The double-wipe method for cleaning is highlighted.

4. Layup and Debulking: Layup involves carefully stacking prepreg plies on the prepared mold according to the work order, ensuring proper orientation and smoothing out wrinkles. Debulking, a process similar to the mold integrity check, is performed after every fourth ply to compress the layers and remove air. The use of release film, breather layer, and thermocouples is explained. Final bagging, including creating pleats in the bagging film for complex parts, is also detailed.

5. Curing: The curing process in an autoclave is described, involving three stages: ramp up, dwell, and ramp down. The importance of controlling temperature, pressure, and vacuum is highlighted.

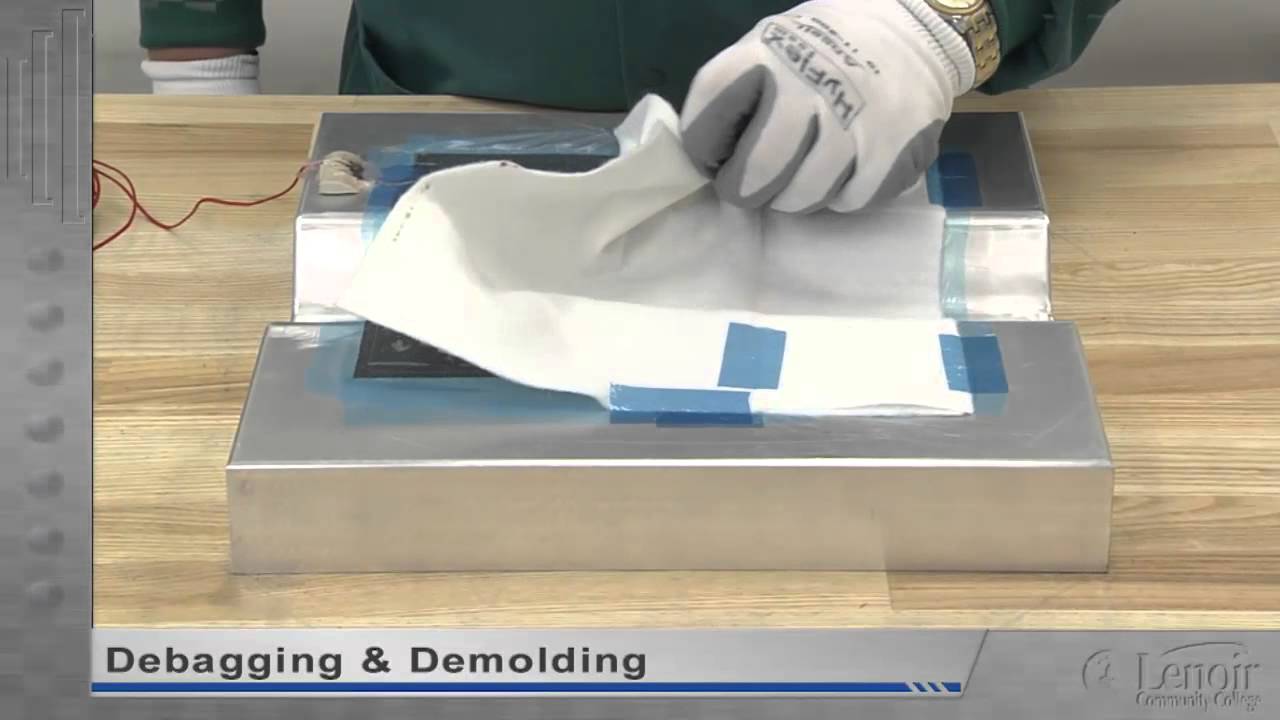

6. Debagging and Demolding: This section explains the careful removal of the cured part from the bag and mold, emphasizing safety precautions and the use of nylon pushers if the part sticks.

7. Trimming and Sanding: Trimming involves marking the part using a template (NTL and RCL lines) and using a die grinder and hand sanding to achieve the final dimensions. Sanding, using an orbital sander and appropriate grit, aims for a perfectly smooth surface.

8. Drilling and Assembly: This section covers the precise drilling process, emphasizing the importance of documentation for hole placement (edge distance, fastener spacing, row spacing), bit selection, and the use of drill cups and stops to ensure accurate and perpendicular holes. The assembly process includes aligning components, applying sealant, installing clecos, and then permanent fasteners (high-lock and Huck bolts). Fillet sealing is also explained.

Throughout the video, the speaker consistently emphasizes the importance of meticulous attention to detail, adherence to process specifications, and the proper use of tools and materials to ensure the production of high-quality aerospace components. The overall message is that while the process is complex, it is achievable through careful planning, execution, and documentation.